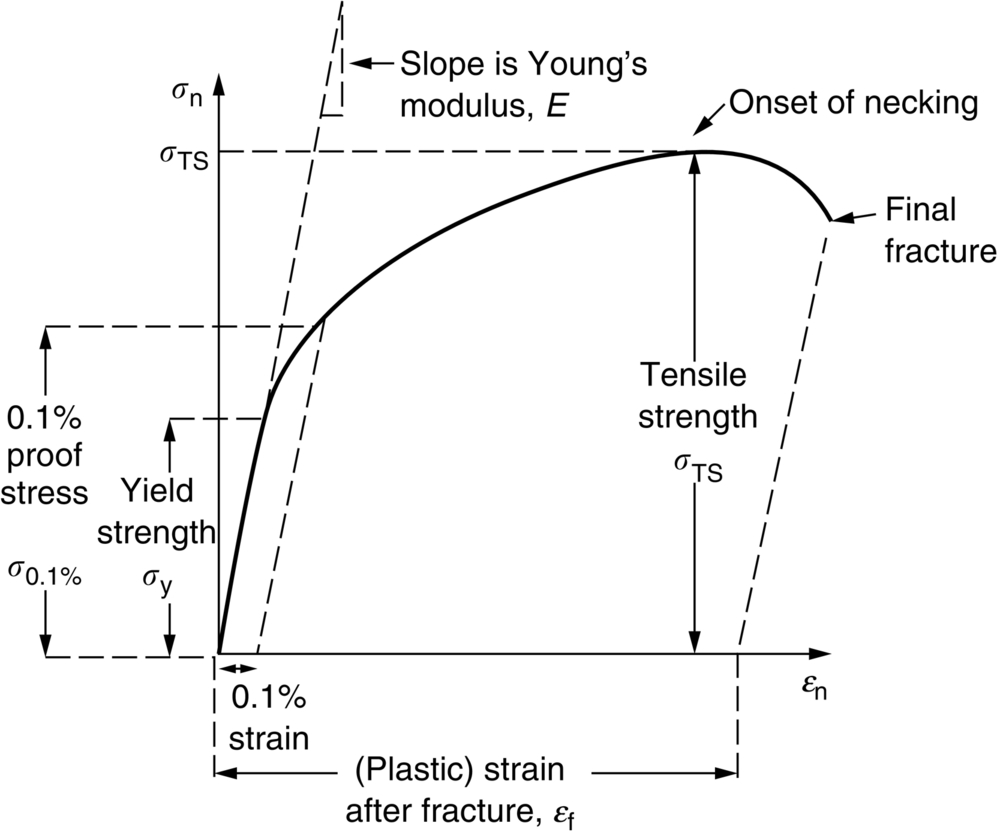

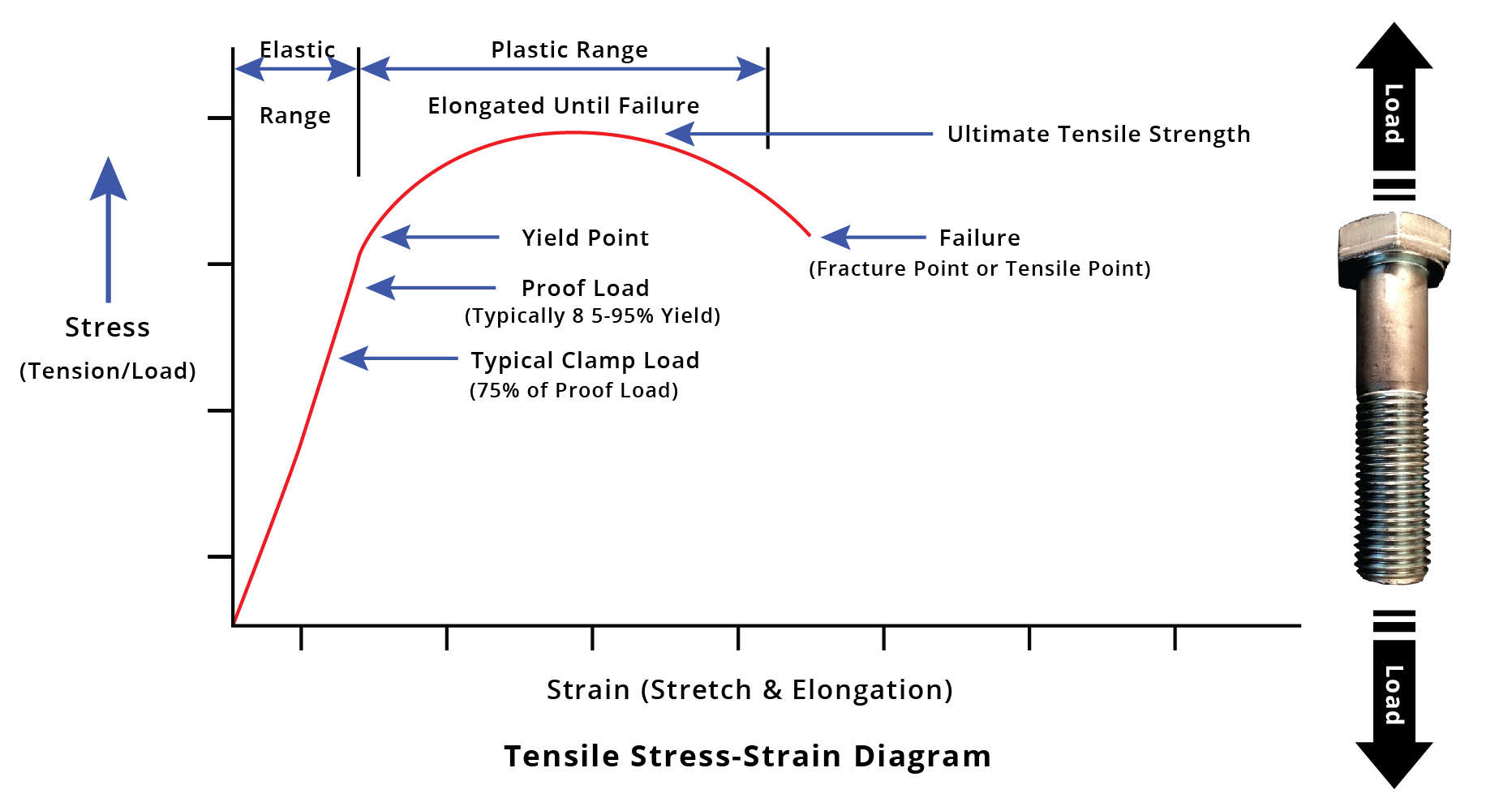

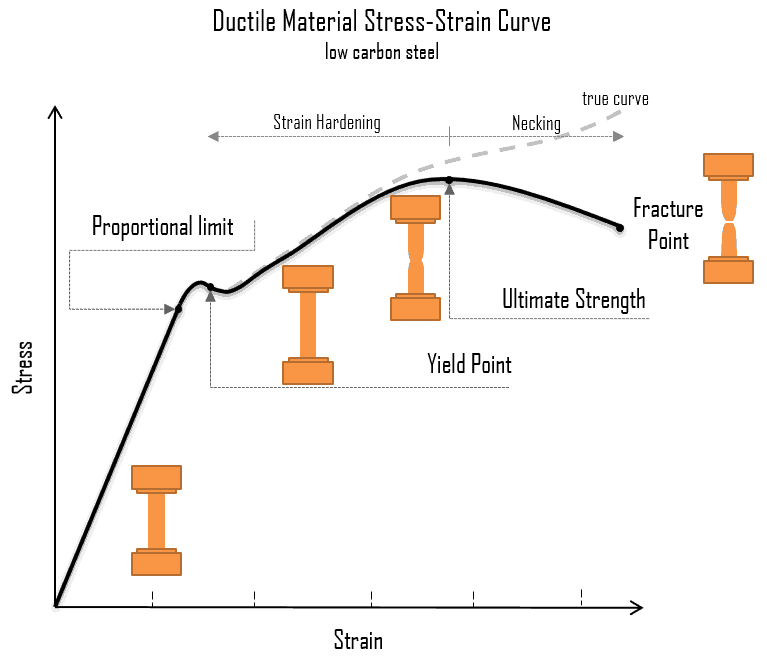

1. Yield Criteria. Three commonly used yield criteria in engineering are: (1) Proportional Limit – The highest stress that maintains a linear relationship on the stress-strain curve, internationally represented as σp. Material is considered to start yielding when stress exceeds σp. (2) Elastic Limit – After loading and unloading a test.. In summary, the key difference lies in their definitions and the points on the stress-strain curve at which they are measured. Yield strength is associated with the onset of plastic deformation, while tensile strength is associated with the maximum stress a material can endure before failure. In general, yield strength is used for designing.

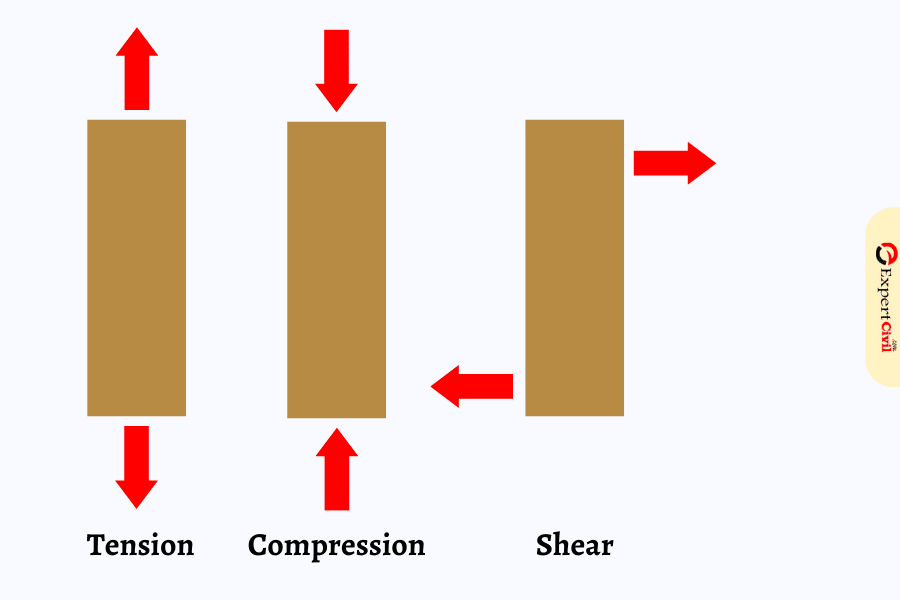

Difference between tensile stress and compressive stress

Yield Strength Vs Tensile Strength What’s The Difference? » Differencess

Tensile strength and yield strength versus testing temperature for a… Download Scientific

StressStrain Curve How to Read the Graph?

Understanding Yield Strength and Tensile Strength Precision Machine Technologies

Yield Strength Definition, Examples , StressStrain Graph, FAQs (2022)

Yield Strength, Tensile Strength, and Ductility Engineer Key

Engineering Stressstrain Curve Total Materia Article

Understanding Tensile Strength The Gund Company

Ultimate Tensile Strength Of Metals

Yield Strength vs. Tensile Strength What’s the Difference?

Tensile Strength and Ductility of Materials Materials Science And Engineering YouTube

Tensile Strength vs Yield Strength Ultra Thin High Strength Stainless Steel Strip

Tensile Strength AHSS Guidelines

How the Tensile Strength vs. Yield Strength of Metals Affect Their Use IMS

Tensile Strength Test of Steel Yield Strength Ultimate Strength All About Civil Engineer

Yield Strength vs. Tensile Strength 6 Key Differences, Pros & Cons, Examples Difference 101

Tensile Strength vs. Yield Strength — What’s the Difference?

classical mechanics Yield Strength versus Ultimate Strength Physics Stack Exchange

What is Yield Strength Yield Point Definition Material Properties

Tensile strength is used to identify the point at which steel goes from elastic (temporary) to plastic (permanent) deformation.. It is worth noting that the tests done on materials to determine tensile strength vs. yield strength are similar. At the beginning stages of failure, the steel will undergo what is called a ductile failure.. For tensile yield strength measurement, for example, standardized testing methods such as ASTM E8 are employed. During the test, the load is increased gradually, and the elongation of the specimen’s gauge length is recorded—often automatically by the testing equipment. This equipment must be capable of applying loads and measuring.